How to make PPEs

3D printed headbands for face shields

There is a shortage in PPEs so I am joining the maker community to make and distribute face shields. Here is a mini blog so you can learn from my mistakes and my research if you also want to do this.

PRINTING THE HEADBANDS

I started with Prusa’s model (which was verified by the Czech Ministry of Health) but I only have one printer (the CR-10), and I couldn’t get it to print in less than 4hrs. *I still have a lot to learn about slicing, so if you have a CR-10, please comment below any configs with PLA that I may have missed to make it faster.

Prusa’s model

Prusa’s design printed in 4 hrs

I decided to try the headband model that Joel shared in his video. This model was made by Erik Cederberg at 3D Verkstan. It is way thinner so it takes a lot less time to print. He made 3 versions (Swedish, European, and North American) and the difference between these is the type of multi-hole puncher that you can use to make the plastic sheets faster.

It took me a little under an hour to print each headband with this model.

Erik Cederberg’s model

Eric Cederberg’s design printed in less than 1 hr

3D Models

Prusa’s models: www.prusaprinters.org/prints/25857-protective-face-shield-rc1

3D Verkstan models: 3dverkstan.se/protective-visor/

What kind of filament can I use?

Preferably PETG, but you can use PLA.

What kind of plastic sheets can I use for the visor?

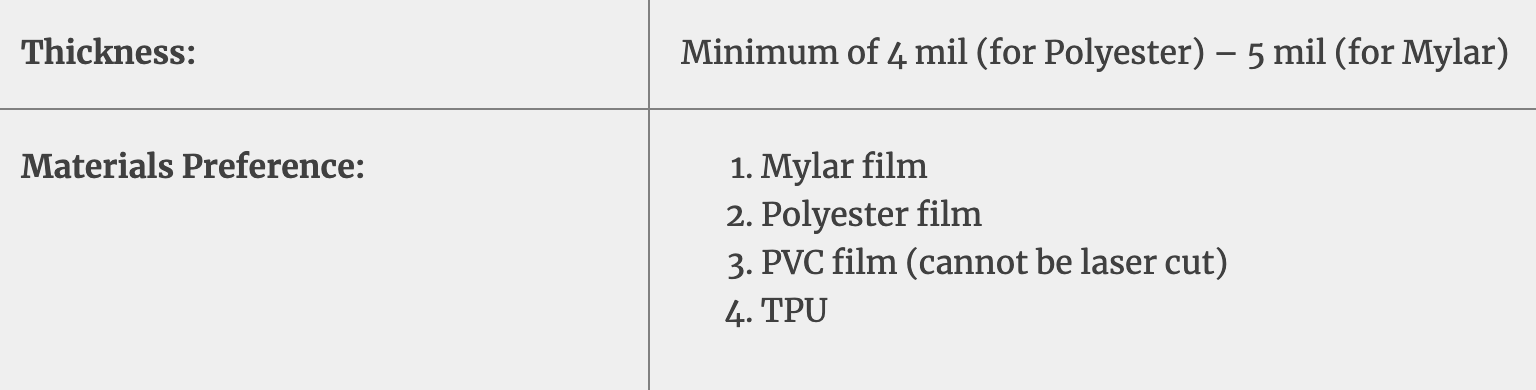

This is a bit controversial because there isn’t ONE answer on this. The University of Michigan's blog says that it needs to be the following:

Taken from specs.engin.umich.edu/um-face-shield/

I couldn’t find a roll of any of these films that would deliver in less than 10 days. So I kept researching and saw that Prusa published these as options:

Laser cut PETG sheets

Laminating foil

Any PETG bottle

I talked to my friend Diana about this and we made the decision to go for the transparency sheets that Joel Telling linked to in his video since it would be the fastest to deliver and we need to get these to Colombia ASAP.

These are the ones I got:

Assembling the face shields

Wear gloves and a face mask while assembling and cutting the transparency sheets. Along the STLs 3D Verkstan, shared prints on where to do the punches. So you can print it on paper and use the paper as a guide to make the holes. I don’t have a regular printer (haha the irony) so I used the 3D print as guide to do the punches.

The holes that you make to the sheets will fit snug on the headband so you don’t need any additional adhesive to hold the visor in place.

I really like how Erik Cederberg’s model can stay on your head without an elastic band. The headband is flexible enough to fit anyone, and it is light enough that it doesn’t slide off.

So flexible!

And comfortable!

Cleaning the face shields

Even though the plastic is heated up to a very high temperature when printing - basically sterilizing the part - I do not think my lab and printer are hospital level sanitized, so my friend Diana will help me clean them before shipping. The University of Michigan suggests Oxivir wipes, Prusa suggests the following:

help.prusa3d.com

The easiest for us is to submerge into soap and water. After cleaning the prints, we will place each dry headband in sterile bags and mark with the type of material used, e.g., “PLA” for the headband, “Polyethylene” for the shield foil. Any unmarked headbands or shield foil may be limited to single use due to uncertain compatibility with disinfecting methods.

I printed! Where do I send them to?

I had my friends Diana and Laura who both have sibling doctors to help me with distribution. We sent them to hospitals in Colombia and NYC.

If you know someone local, start giving the shields to them as soon as possible. I am sending the ones I am currently printing to Colombia since I have a direct contact at a hospital there. After these I will be sending to another direct contact in New York.

If you don’t know anyone in the medical industry, you can volunteer your 3D printer! There are maker spaces around the world who are taking your 3D printed headbands! They print the shields, laser cut the visors, sanitize them, add elastic bands, and get them in hands of medical professionals as quickly as they can. So all you have to do is print and send the headbands to these maker spaces.

Make sure you go to their website, sign up as a maker, and look at the models that they are currently producing. Most places are also looking for people who can 3D print, laser cut, and help with logistics and planning.

Argentina - Makers Argentina

Australia - covidsos.com.au

Canada - Covidstop.ca

France - Covid3D.fr

Germany - Maker vs. virus

Mexico - coronavirusmakers.mx

Netherlands - schonebakkesdenhaag.nl and makers4all.eu/nl/

Sweden - 3D Verkstan

UK - 3Dcrowd UK

USA -

Ann Arbor, Michigan - maker-works.com

Baltimore, Maryland - openworksbmore.org

Baltimore, Maryland - wethebuilders.com

Sacramento, California - opshieldsup.org

**If you know about other maker communities in the world, please comment with a link to them below~ I will edit this post to include everyone.

What else can I make?

You can also join this Facebook group Open Source COVID19 Medical Supplies where makers share other supplies which can be printed. Make sure you have communication with medical professionals to see if they can use any supply you might think of making before producing them.

Why not 3D Printed masks?

Speaking of 3D printing PPEs, here is a well versed tweet series from Naomi Wu on why not 3D printed masks:

TLDR; 3D printed masks are not a useful thing at the moment. You can sew a more effective mask in less time than it takes to prep and post process a 3D printed one.

— Naomi Wu 机械妖姬 (@RealSexyCyborg) March 19, 2020

Yes they look very cool- but we are not cosplaying here. Make face shields. @Prusa3D has an excellent design.

Final thoughts..

Please consider using your 3D printer to help make face shields for medical professionals. If you print any of the ones I did, hit @erikcederb and @josefprusa on twitter and say THANK YOU.

If you don’t have a 3D printer, but you’ve always been curious about getting one, this is the perfect time to order one. Not only will you learn how to 3D print with these face shields (#LEARNSOMETHING!), but you will also help medical professionals in your community.

Start printing and code on dudes and dudettes!